- Company

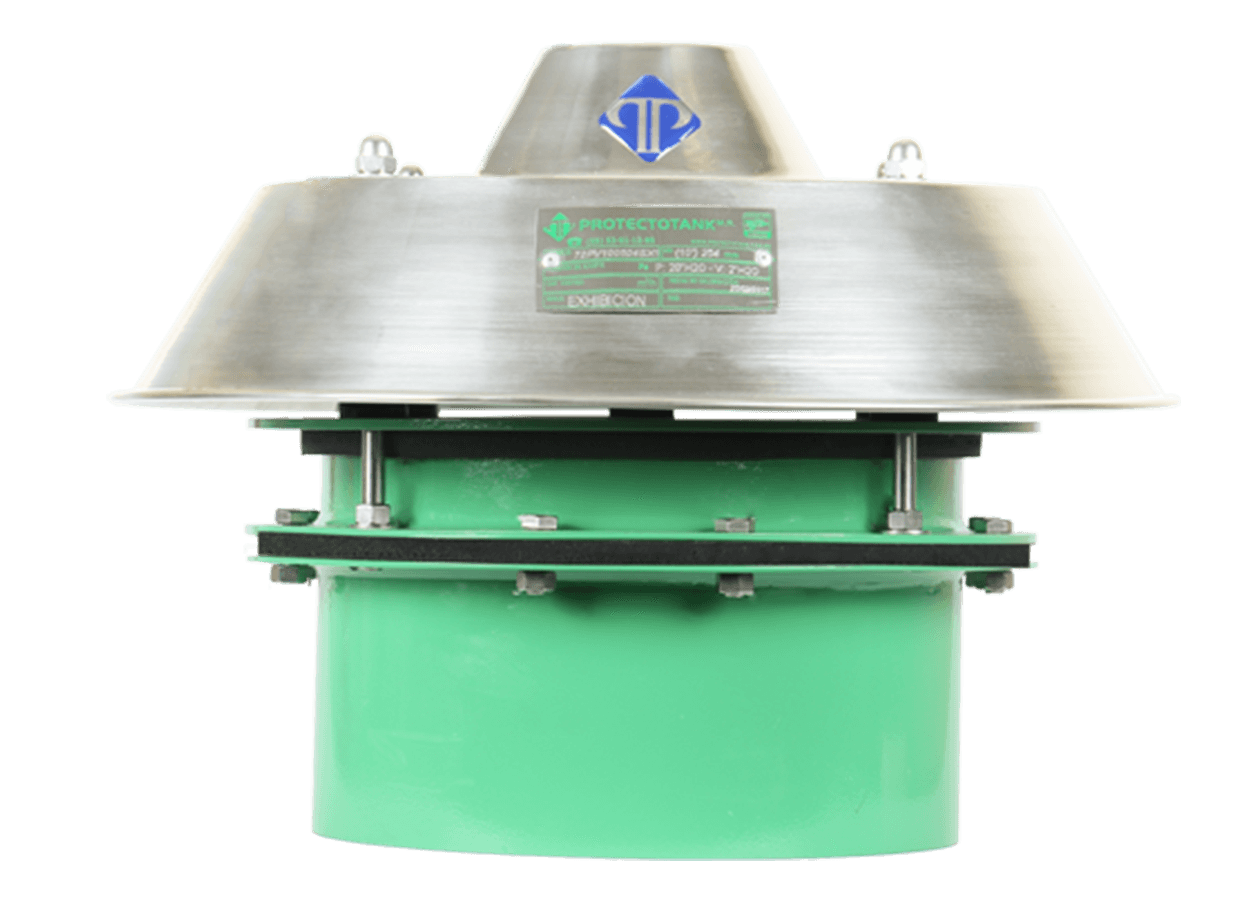

Pressure and vacuum valves are essential safety devices designed to protect atmospheric storage tanks from the harmful effects of overpressure and excessive vacuum. By detecting pressures beyond established limits, these valves open automatically, allowing excess fluid or air to enter or exit in a controlled manner, thus avoiding costly damage, reducing product loss, and minimizing environmental contamination, while ensuring safe operations.

Accuracy: Precise opening and closing at the set pressure.

Ventilation systems in fuel and biofuel tanks.

Ethanol tanks for beverages.

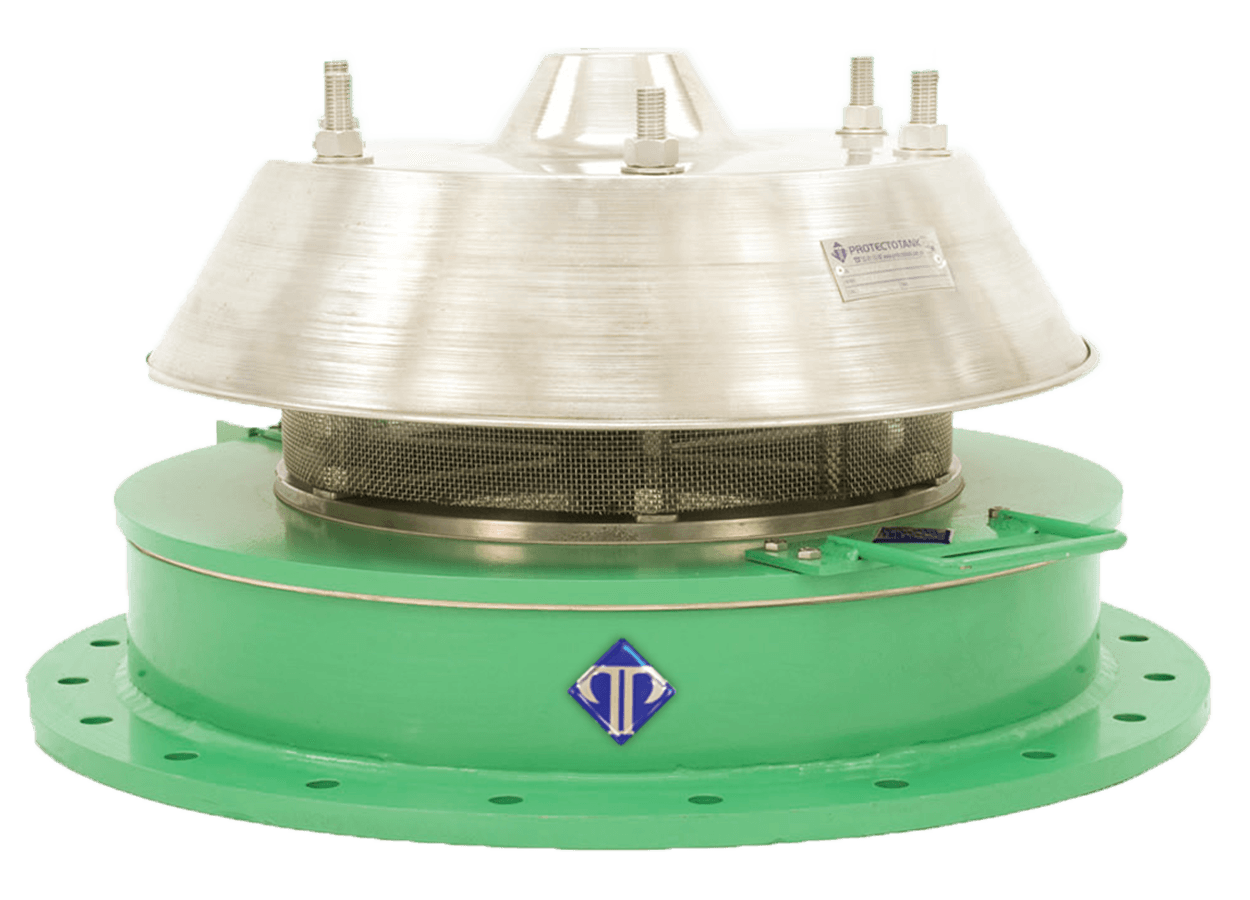

Controls the inflow and outflow of gases and vapors in atmospheric or semi-pressurized storage tanks, providing significant benefits such as emission control to the atmosphere, cost savings, environmental protection, and tank safety by preventing flame flashback inside the tank, which could lead to an explosion. The Pressure-Vacuum Valve with integrated arrestor can be adjusted for independent pressure or vacuum values according to the storage tank design, ensuring protection against excessive overpressure or vacuum that can damage the tank and pose risks to personnel and facilities.

The tank venting valve controls the inflow and outflow of gases and vapors in atmospheric or semi-pressurized storage tanks, offering significant benefits such as emission control to the atmosphere, cost savings, environmental protection, and tank safety by preventing flame flashback inside the tank, which could lead to an explosion.

The Series 72 emergency venting system for pneumatic systems is designed to control overpressure or vacuum inside powder, grain, and general solid silos. This effect, caused by pneumatic transportation or thermal effects within the silo, can result in severe damage to the silo structure as well as peripheral equipment.

In the event of a fire outside a storage tank, this device acts as a safety valve, relieving excess pressure inside the tank and preventing the possibility of an explosion. It operates when overpressure occurs inside or when there is a fire outside the tank.

It controls the breathing of atmospheric or semi-pressurized storage tanks, providing the key benefit of controlling emissions into the atmosphere while generating savings, increased safety, and environmental protection. The daily operation of storage tanks necessitates venting regulation devices, as their absence would result in the emission of product vapors, leading to monetary losses due to shrinkage, atmospheric pollution, and an increased risk of fire.

Its main function is to control the breathing of atmospheric or semi-pressurized storage tanks. Its greatest benefit is the control of emissions into the atmosphere, generating economic savings, greater process safety, and environmental protection.

It controls the breathing of atmospheric or semi-pressurized storage tanks, offering the key benefit of controlling emissions into the atmosphere while generating savings, enhanced safety, and environmental protection. The daily operation of storage tanks necessitates venting regulation devices, as without them, product vapors would be released, leading to financial losses from shrinkage, atmospheric pollution, and an increased risk of fire.

It controls the breathing of atmospheric or semi-pressurized storage tanks, providing the key benefit of controlling emissions into the atmosphere while generating savings, increased safety, and environmental protection. The daily operation of storage tanks requires vent regulation devices, as their absence would result in the release of product vapors, leading to financial losses due to shrinkage, atmospheric pollution, and an increased risk of fire.

It controls the breathing of atmospheric or semi-pressurized storage tanks, offering the primary benefit of controlling emissions into the atmosphere while generating savings, enhancing safety, and protecting the environment. The daily operation of storage tanks necessitates vent regulation devices, as their absence would result in the release of product vapors, leading to financial losses due to shrinkage, atmospheric pollution, and an increased risk of fire.

“At PROTECTOTANK, I find the necessary equipment for storage tanks to better control emissions to the atmosphere and reliable safety and control devices.”

“The support and advice from Azteca regarding our project has always had a positive impact and contributed to significant achievements in decision-making.”

“I highly recommend the company Protectotank to help companies in the Oil & Gas sector protect their facilities and care for the environment.”

“The result for the evaluated period of 2023, reviewed by the corresponding departments of GASODUCTOS SERVICIOS CORPORATIVOS Y DE ADMINISTRACIÓN S DE RL DE CV / GDT, was a 95.83% compliance, which qualifies them as: Highly Reliable Supplier.”

“The final rating for this period (September-December 2018) obtained by your company was 100% out of 100%, classifying them as a Recommended Supplier.”

“The users are satisfied with the service from CC AZTECA, and the supplier has shown flexibility and professionalism at all times.”

“I highly recommend the company Corporación Constructora Azteca to help Fuel Terminals comply with the requirements of NOM-006-ASEA-2017.”

“At PROTECTOTANK, I find the necessary equipment for storage tanks to better control emissions to the atmosphere and reliable safety and control devices.”

“The support and advice from Azteca regarding our project has always had a positive impact and contributed to significant achievements in decision-making.”

“I highly recommend the company Protectotank to help companies in the Oil & Gas sector protect their facilities and care for the environment.”

“The result for the evaluated period of 2023, reviewed by the corresponding departments of GASODUCTOS SERVICIOS CORPORATIVOS Y DE ADMINISTRACIÓN S DE RL DE CV / GDT, was a 95.83% compliance, which qualifies them as: Highly Reliable Supplier.”

“The final rating for this period (September-December 2018) obtained by your company was 100% out of 100%, classifying them as a Recommended Supplier.”

“The users are satisfied with the service from CC AZTECA, and the supplier has shown flexibility and professionalism at all times.”

“I highly recommend the company Corporación Constructora Azteca to help Fuel Terminals comply with the requirements of NOM-006-ASEA-2017.”

Teléfono: 5590635212 ext. 1104

Correo: amontiel@protectotank.com.mx

Teléfono: 5590635211 ext. 1105

Correo: arturo.rangel@protectotank.com.mx

Teléfono: 5590635213 ext. 1105

Correo: baleria.angeles@protectotank.com.mx

Teléfono: 9219801056 ext. 3102

Correo: claudia.vazquez@protectotank.com.mx

Teléfono: 5590635215 ext. 1107

Correo: eduardo.vizuet@protectotank.com.mx

Teléfono: 5590635214 ext. 1106

Correo: estrella.pina@protectotank.com.mx

We are here to help you. You can reach out to us through WhatsApp, email, or phone. We also invite you to follow us on our social media to stay updated on our latest news.

+52 55 53 01 12 95