- Company

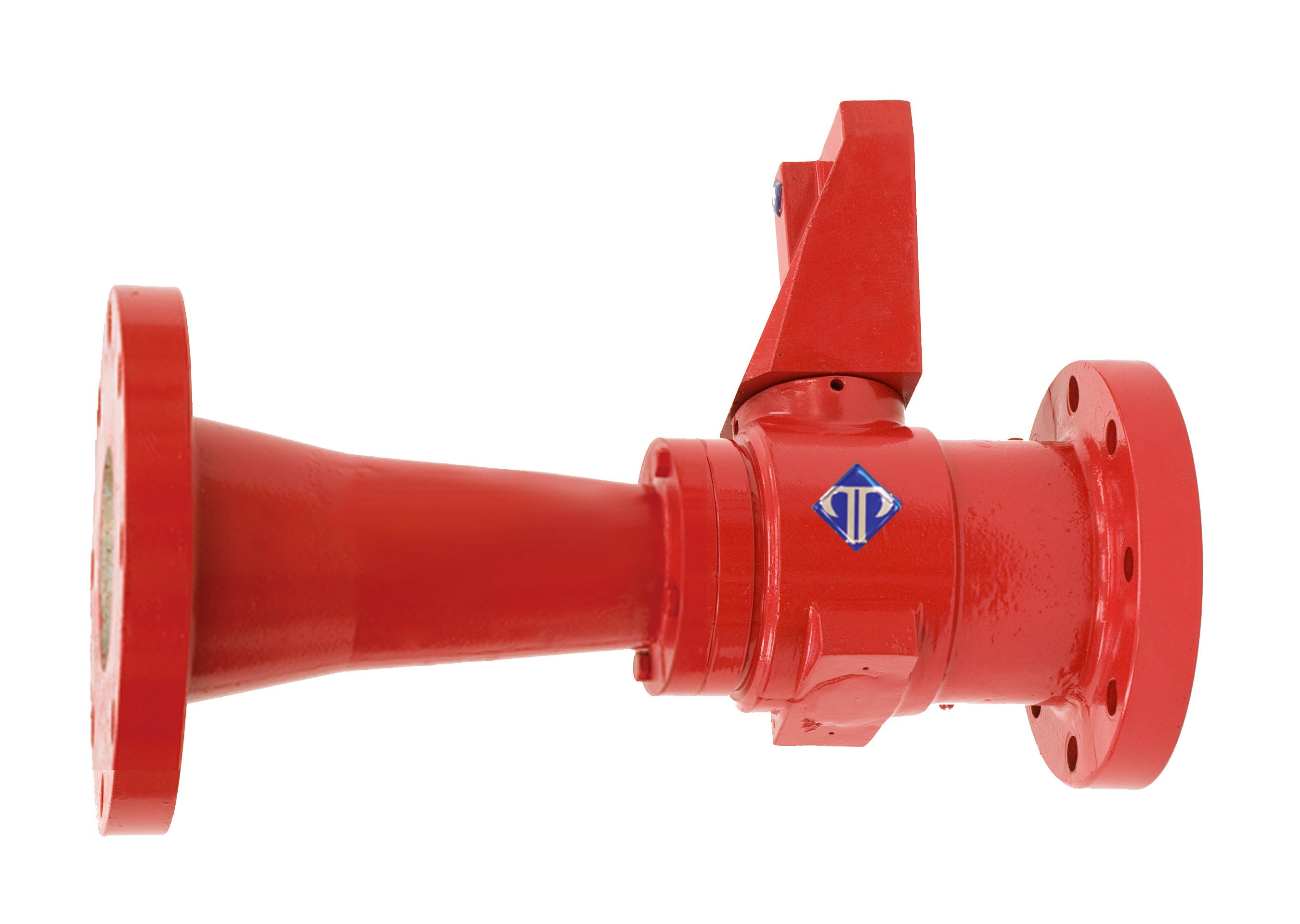

Foam chambers are designed to form and inject non-flammable,

low-expansion foam directly onto the liquid surface inside the

storage tank, thus creating a layer capable of extinguishing a fire

by eliminating oxygen.

Our foam chambers are compatible with all concentrates available on

the market: protein-based, fluoroprotein, AFFF, and AR-AFFF.

Body Materials: Carbon steel

Internal Material: Venturi, screws, meshes, orifice plate, and

butterflies in stainless steel

Ventilation systems in fuel and biofuel tanks.

Ethyl alcohol tanks for beverages.

Series 95 foam chambers are designed to form and inject low-expansion, non-flammable foam directly onto the liquid surface inside the storage tank. This creates a layer capable of extinguishing the fire by eliminating oxygen. These chambers are typically installed on the sides of atmospheric storage tanks (fixed and floating roofs) above the maximum liquid level, directly connected to the water/foam mixture supply line.

Counter-pressure injection is designed to form a layer on the liquid's surface, but from the bottom of the tank. In the event of a fire, if traditional foam chambers become damaged or fail, sub-surface injection can easily replace them.

“At PROTECTOTANK, I find the necessary equipment for storage tanks to better control emissions to the atmosphere and reliable safety and control devices.”

“The support and advice from Azteca regarding our project has always had a positive impact and contributed to significant achievements in decision-making.”

“I highly recommend the company Protectotank to help companies in the Oil & Gas sector protect their facilities and care for the environment.”

“The result for the evaluated period of 2023, reviewed by the corresponding departments of GASODUCTOS SERVICIOS CORPORATIVOS Y DE ADMINISTRACIÓN S DE RL DE CV / GDT, was a 95.83% compliance, which qualifies them as: Highly Reliable Supplier.”

“The final rating for this period (September-December 2018) obtained by your company was 100% out of 100%, classifying them as a Recommended Supplier.”

“The users are satisfied with the service from CC AZTECA, and the supplier has shown flexibility and professionalism at all times.”

“I highly recommend the company Corporación Constructora Azteca to help Fuel Terminals comply with the requirements of NOM-006-ASEA-2017.”

“At PROTECTOTANK, I find the necessary equipment for storage tanks to better control emissions to the atmosphere and reliable safety and control devices.”

“The support and advice from Azteca regarding our project has always had a positive impact and contributed to significant achievements in decision-making.”

“I highly recommend the company Protectotank to help companies in the Oil & Gas sector protect their facilities and care for the environment.”

“The result for the evaluated period of 2023, reviewed by the corresponding departments of GASODUCTOS SERVICIOS CORPORATIVOS Y DE ADMINISTRACIÓN S DE RL DE CV / GDT, was a 95.83% compliance, which qualifies them as: Highly Reliable Supplier.”

“The final rating for this period (September-December 2018) obtained by your company was 100% out of 100%, classifying them as a Recommended Supplier.”

“The users are satisfied with the service from CC AZTECA, and the supplier has shown flexibility and professionalism at all times.”

“I highly recommend the company Corporación Constructora Azteca to help Fuel Terminals comply with the requirements of NOM-006-ASEA-2017.”

Teléfono: 5590635212 ext. 1104

Correo: amontiel@protectotank.com.mx

Teléfono: 5590635211 ext. 1105

Correo: arturo.rangel@protectotank.com.mx

Teléfono: 5590635213 ext. 1105

Correo: baleria.angeles@protectotank.com.mx

Teléfono: 9219801056 ext. 3102

Correo: claudia.vazquez@protectotank.com.mx

Teléfono: 5590635215 ext. 1107

Correo: eduardo.vizuet@protectotank.com.mx

Teléfono: 5590635214 ext. 1106

Correo: estrella.pina@protectotank.com.mx

We are here to help you. You can reach out to us through WhatsApp, email, or phone. We also invite you to follow us on our social media to stay updated on our latest news.

+52 55 53 01 12 95